Embrace The Future Of Customization With 3D CNC Machining Services

In the digitized and evolving manufacturing landscape, technological advancements continue to influence processes and production. Adopting the latest 3D CNC machining services is at the forefront of progression. Indeed, it is the way to unlock the personalization that industries expect to have in the competitive arena.

This blog will evaluate the future of manufacturing with 3D machining and how industries can get their customized products when hiring Chennai CNC machining services.

3D CNC machining – What you need to know

CNC machining and 3D machining are the most popular manufacturing processes. Both are helpful in fabricating any product designs. Though rapid prototyping and CNC machining are quite popular among industries, the capabilities that you achieve with 3D CNC machining services are transforming the way that the parts are produced.

3D machining is also referred to as additive manufacturing. This means, that in this process, the material is built employing adding layers of materials at a time. 3D printing involves the use of digital files to guide the creation of a physical product layer by layer. This process ensures customizing the workpiece.

Benefits of 3D machining in the manufacturing sector:

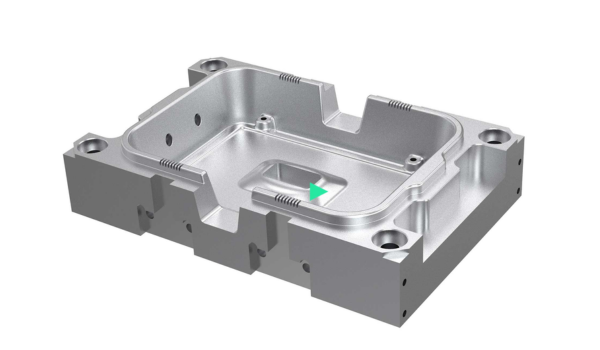

Potential to produce complex parts

It is always a tough task to create complex parts using traditional technologies. The onset of 3D CNC machining services has arisen as a beacon of hope in the form of additive manufacturing. With the help of 3D machining, you can integrate the complexities that are typically faced while creating complicated parts.

Precision beyond expectations

Precision and accuracy are the cornerstones of any industry. In specific industries such as the medical and automotive sectors, even a slight deviation from the design can lead to drastic concerns. Here comes the CNC machining with 3D printing that helps in achieving tolerances in micrometres.

Environmentally Friendly

Typical CNC machining involves a subtractive approach that cuts away the material from the workpiece. Hence, after machining, the place is messy and has to be cleaned off and disposed of of the removed materials. However, with 3D CNC machining services and additive manufacturing, this is not the case. Here the process forms a part of the build platform by feeding into the machine. Hence there is no mess, meaning that 3D machining gives less unused waste.

3D printing is considered a more sustainable alternative as it reduces energy consumption and material waste.

Single-step manufacturing

Traditional manufacturing involves various steps to produce parts. Undergoing multiple stages can impact the quality and manufacturability of the part. But these nuisances are effectively dealt with by 3D CNC machining services, which can manufacture an entire part in a single step. The typical process involves initial CAD design, uploading it to the 3D printer and printing in a single step within a few hours.

Faster lead times

The biggest benefit of 3D CNC machining is its capability to achieve quick lead times to market. 3D technology can be used in the early stages of prototyping and this fastens the product development. The designing team can easily render the 3D design, evaluate it, make modifications as required and validate the final CAD software design.

The power of customization with 3D CNC machining services

Leveraging CAD/CAM software

In this kind of machining, CNC machines use CAD/CAM software that helps in creating customized 3D models and feed into the machining instructions. The capability empowers tweaking the 3D models and making any adjustments related to dimensions, features or geometries in the CAD model, thus fulfilling specific demands without the need for new tooling.

Custom creations

3D technology in CNC machining paves for new opportunities for custom-made parts. Rather than relying on conventional expensive setups, now you can build a digital model of a product through 3D CNC machining services. This technology has accelerated the growth of various industries in creating custom prototypes and product designs without any high upfront costs.

Flexibility to adopt quick changes

3D machining enables manufacturers to have the flexibility to make quick changes and corrections when they identify errors in designs or features. This adaptability is highly appreciated with 3D CNC machining and manufacturers can come up with prototypes that are flawless in terms of features, functionality and design. When the designing team detects any error, they can easily implement corrections and thus the final product is customized and built as per customer requirements.

Meeting special needs of industries

3D CNC machining services allow manufacturers to have precise customization based on their unique demands. Whether the requirement falls on selecting the material, making changes in dimensions or tailoring components for special purposes, 3D machining enables fine-tuning parts for their specific needs.

Custom machining for low-volume CNC machined parts

The benefits of 3D CNC machining are particularly recognized in fulfilling low-volume custom machined parts. Whether it is just 50 parts or 5000 custom machined parts, CNC machining with 3D technology can achieve the quantities effortlessly.

Versatility in material selection

3D technology is compatible in working with diverse materials such as plastics, photopolymers, ceramics, titanium, aluminium and photopolymers. Based on the type and requirement of the project, you can choose the materials and get complete customization with 3D CNC machining services.

Design freedom

Flexibility in designing is the biggest reason to choose 3D CNC machining. This innovative technology has enabled designers to create intricate shapes with greater efficiency. You can now customize the designs so that they meet your aesthetic and performance needs, still, without using more materials.

With traditional designing, there are many constraints. However, with 3D technology in CNC machining, you can design parts that are considered too complex to create.

Setting the new benchmarks in customization – 3D CNC machining services from Epsilon Engineering

The rise of customer-oriented and customized products urges to adopt innovations in machining and 3D CNC machining is one among them. This technology has revolutionized customization in manufacturing parts. Instead of going mass production that fails to meet customer requirements, this unique approach helps in tailoring the products as per the preferences of customers.

Precision 3D CNC machined parts from Epsilon Engineering, the leading CNC engineering solutions, now businesses have access to create precise and custom parts. The benefits that you get from our reliable CNC machining solutions are manifold. If you look to create unique parts that have exceptional performance, then leave the task to our experts. Our sophisticated CNC machines have a great range of efficiencies in achieving personalized products with tight tolerances and higher surface quality. We offer our clients affordable and on-demand 3D machining services for creating customized prototypes and parts. Our fully automated 3D CNC machining services promise clients cost-effective and personalized parts at quick turnaround times.

Related post:

CNCMachining Supplier

CNCMachining Center

3D CNCMachining Services

CNCMachining for Acrylic

Alloy Machining Services

High Precision Machining Company

CNCTitanium Machining

Low Volume CNCMachining

Designing Products for Manufacturing

Prototype Solutions Every Product Development Team Must Know

Prototyping Services

Traditional and Rapid Prototyping Services

Functional Prototype Development

Rapid Prototyping Services

Significance of 5-Axis CNCMachining in Your Business Growth

Applications of VMC Machining Technology

Application of CNCMilling in Modern Industries