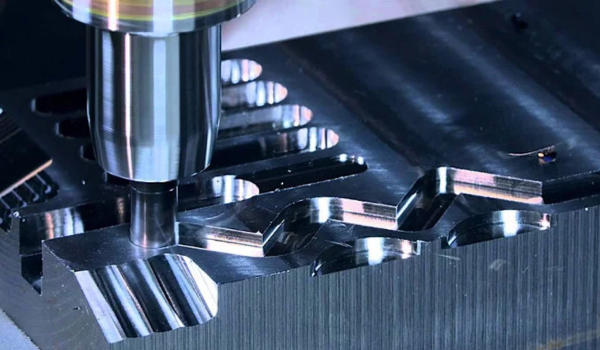

The application of CNC machining has grown considerably in recent years. There are diverse industrial sectors that deploy the essential CNC milling process into their featured operations. CNC or Computer Numerical Control milling is a revolutionary technology in which a computer-controlled rotary cutting tool eliminates the excess materials from a workpiece and makes it a finished one.

In this, let us explore the application of CNC milling in numerous industries and get to know the crucial process that has transformed the modern industrial world.

IIOT

Thanks to the improvements of CNC milling with its sensors and load cells, now it is quite possible to acquire promising advantages in implementing pre-programmed tasks. Some of the IIOT industries, elaborately termed Industrial Internet of Things (IIoT) industries are smart manufacturing industries, advanced industries or industry 4.0.

Deploying CNC milling into such smart industries enables to achieve:

- Transform the businesses into more efficient and more successful

- Establish connections with technology assets, supply chain and workforce to deliver live data

- Make use of data acquired from the above connections for informed and quicker decisions.

- Adopt advanced and integrated technologies such as sensors, robots and 3D printing across their business operations.

- Improved accuracy and better production yields

- By connecting CNC milling machines together across networks, data sharing is possible and this eradicates human error and streamlines all processes within the business.

To put it simply, CNC milling in the business processes can obviously enhance performance. Lean manufacturing is the core for IIOT industries and CNC milling is the key to that.

Aerospace

CNC milling is truly engineering the bright future of flights. Aerospace CNC milling embraces computer-aided tools and components and manufactures aircraft parts. Right from lightweight materials such as aluminium and composites to heat-resistant and robust metals such as titanium, the application of CNC milling machines goes a long way in operating with all kinds of materials.

The aerospace industry is rapidly emerging concerning the latest technology and innovations. Crucial aspects such as structural integrity of airframes, efficiency of propulsion systems, and more, there are varied aspects where there is a need for precision-crafted components.

A quick fact for you to know here. Global News Wire says that the aerospace & defence market across the globe is estimated to attain $1047.07 billion in 2026 and the CAGR is 8.5%.

Ways in which CNC milling is revolutionizing aerospace industries include:

- 5-axis milling machining is useful for manufacturing complex components of an aircraft.

- Utilized along with 3D printing technologies for accomplishing exceedingly precise finishing and accuracy.

- The 5-axis milling process is perfect to tackle the precision, technical specifications, and requirements related to aerospace components.

- The CNC milling process is efficient in manipulating and drilling parts along with the X, Y, and Z axes.

Advantages of using CNC milling in the aerospace industrial sector

- Versatility

Aircraft components are lightweight and with CNC milling can deal with diverse materials such as titanium, aluminium, composites and distinguished alloys.

- Precision engineering

CNC milling is best recognised for its accuracy in producing varied complex parts in the aerospace industry.

- No room for errors

With CNC milling, you can automate the processes and hence there is no scope for typical human errors.

- Cost savings

This computerised operation reduces the requirements of deploying an immense team of workers. Hence labour cost is reduced.

- Aircraft Safety

Aerospace components must fulfil rigorous safety and quality standards of regulatory authorities. CNC milling ensures meeting those requirements effortlessly.

Medical Industry

CNC milling with its rotary cutting tool eliminates material from a workpiece and produces high-precision complex parts. Right from implants to surgical instruments, there are a range of medical devices that can be produced with CNC milling, which include:

- Prototyping of medical devices

- Surgical equipment and endoscopic tools manufacturing

- Components for diagnostic equipment

- Orthopaedic implants like hip and knee replacements

- Milling machines often produce parts for medical researchers in the biomedical industry,

Most advanced equipment in the medical industry demands extremely precise tolerances and this can be easily achieved by CNC milling machines.

Essential reasons for using CNC milling machines in the medical industry:

- Material Versatility

- High Production Volume

- High-Speed Production

- Precision and Accuracy

- Custom Designing

EMS industry

EMS, the Electronic Manufacturing Services industry refers to those companies that design, produce, test and distribute services for electronic components and assemblies for OEMs, original equipment manufacturers.

3-axis and full 5-axis milling machines help in producing highly accurate and quality parts for EMS industries. There are a variety of milling processes utilized in manufacturing high-precision parts.

- Surface milling

- Face milling

- Gear milling

- Angular milling

- Form milling

- Profile milling

CNC milling machines are optimal for prototyping and producing parts for electronic devices such as handheld devices, industrial machinery and more. Some of the segments where EMS manufacturers can deploy CNC milling and manufacture complex electronics and other designs are:

- Printed Circuit Boards (PCBs)

- Semiconductors

- Casings and Enclosure Parts

- Heat Sinks

- Connectors and Sockets

There is emerging demand in the electronics industry and this indicates a sharp attention towards producing electronic parts with high-precision and quality aspects. CNC milling has just revolutionized the EMS industries such as the tech industry, consumer electronics, power electronics and the semiconductor industry.

Key Takeaways

As the popularity of CNC milling technology grows, so are the varied applications in diverse industries. CNC milling is a versatile technology beneficial in getting tasks done faster and more efficiently. CNC milling machines can mass manufacture products and can precisely customize components. This is the crucial reason that most manufacturers employ CNC milling in their business operations to make parts.

We have looked into how CNC milling has its applications in various industries. It doesn’t matter which industry it is, CNC milling practice can definitely suit its needs.

On-demand CNC milling services from Epsilon Engineering

Epsilon Engineering has its inevitable role when it comes to leveraging the power of CNC milling for industrial growth. Now companies can get their prototypes and production parts efficiently and precisely with us. Our highly qualified team and precise machinery can give you any customized design, no matter how complex it is. We specialize in manufacturing end-to-end use production parts and custom prototypes.

Our 5-axis indexed milling processes can produce complex geometric shapes. Our immense capabilities can fuel the growth of industries that look to take advantage of CNC milling.

Related Post

CNC Machining Supplier

CNC Machining Center

3D CNC Machining Services

CNC Machining for Acrylic

Alloy Machining Services

High Precision Machining Company

CNC Titanium Machining

Low Volume CNC Machining

Designing Products for Manufacturing

Prototype Solutions Every Product Development Team Must Know

Prototyping Services

Traditional and Rapid Prototyping Services

Functional Prototype Development

Rapid Prototyping Services

Significance of 5-Axis CNC Machining in Your Business Growth

Applications of VMC Machining Technology

Application of CNC Milling in Modern Industries